Step 1: Pre-Drying and Controlled Storage of Raw Materials

The production cycle begins with the pre-conditioning of thermoplastic raw materials. These polymers undergo controlled thermal drying to eliminate residual moisture that can negatively affect melt flow, extrusion uniformity, and interlayer bonding. Once dried, the materials are stored in a fully enclosed, humidity-controlled warehouse, effectively preventing reabsorption before processing.

Step 2: Enclosed Material Handling and Precision Extrusion

Through the pneumatic conveying system, dried materials are transported directly to the extrusion line, minimizing exposure to ambient air. The extrusion system integrates:

● Precisely regulated heating zones for optimal polymer melting behavior

● Controlled cooling channels to ensure filament diameter stability and reduce internal stress

● Automated spooling for uniform winding and reduced tangling or deformation

This closed-loop design preserves material integrity, reduces contamination risks, and maintains dimensional tolerance across large production volumes.

Step 3: Post-Extrusion Drying and Thermal Stabilization

Unlike standard procedures, Inslogic incorporates a secondary drying step after extrusion and spooling. Each filament spool is:

● Placed in a temperature-regulated drying chamber

●Conditioned for three hours at 49–63°C, with the temperature calibrated according to filament type (e.g., functional, general, or engineering filaments).

This additional drying phase removes any residual internal moisture and enhances the long-term stability of the finished product.

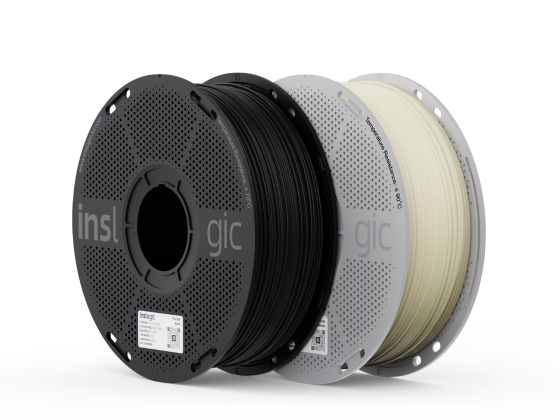

Step 4: Vacuum Sealing and Protective Packaging

Following thermal conditioning, each spool is vacuum-sealed with a desiccant packet in moisture-barrier packaging. This step safeguards the filament during storage and transport, ensuring that it remains dry and print-ready out of the package—even after extended shelf time.

The Importance of Moisture Management in Filament Production

Moisture absorption is a common yet critical issue in thermoplastic filament manufacturing. Exposure to humidity can lead to poor extrusion consistency, bubbling, stringing, reduced strength, and layer adhesion failure. Inslogic’s fully integrated drying, handling, and packaging process mitigates these issues at every stage, ensuring that each spool meets the demands of precision printing environments.

Explore Inslogic’s advanced 3D printing materials and production standards at www.inslogic3d.com