How to properly protect and store your 3D printer filament is one of the most important things to know. 3D printer filament requires special accommodation, specifically regarding humidity control. 'Wet' filament can become brittle, bubbly, or stringy, leading to failed prints, sputtering (as stored moisture is heated during the printing process), and even nozzle blockages. Therefore, experiencing failed prints and obtaining low-quality results will not only waste your time but also your money.

In this article, we will guide you through some of the best and cost-effective ways to store and protect your 3D printer filament, ensuring high print quality, increased accuracy, and savings in both time and money. Let’s dive right into it.

Is Your Filament Wet?

It’s difficult to tell if your filament is wet just by looking at it. If you notice that the surface of your filament is not smooth and there are tiny bubbles inside, it means that your material is very wet.

You will know your filament is wet when you try to print with it. The material continues to ooze out even after the extruder motor has stopped pushing it through the hotend. Popping and cracking sounds can be heard during extrusion. The filament produces a print with a fuzzy surface texture rather than the usual smooth finish. All these common signs indicate that your filament is humid, and the spool needs to be dried.

-

Popping or cracking sounds when extruding

-

Severely reduced part strength and layer adhesion

-

Uneven extrusion lines

-

Severe stringing, blobbing, or oozing

-

Uncharacteristically textured or fuzzy surfaces on prints

Printing with wet and dry filament (Source: howto3dprint)

Printing with wet and dry filament (Source: howto3dprint) How To Dry Wet Filament

To dry the wet filament, the answer is simple, you need to dry out your filaments and know how to store them properly. But be careful not to heat the filament too much otherwise it can transition to a glass phase and fuse the entire spool together. Your whole spool will be ruined. It’s important to research the appropriate temperatures for the material that you need to dry, and keep the tempreture a little under that.

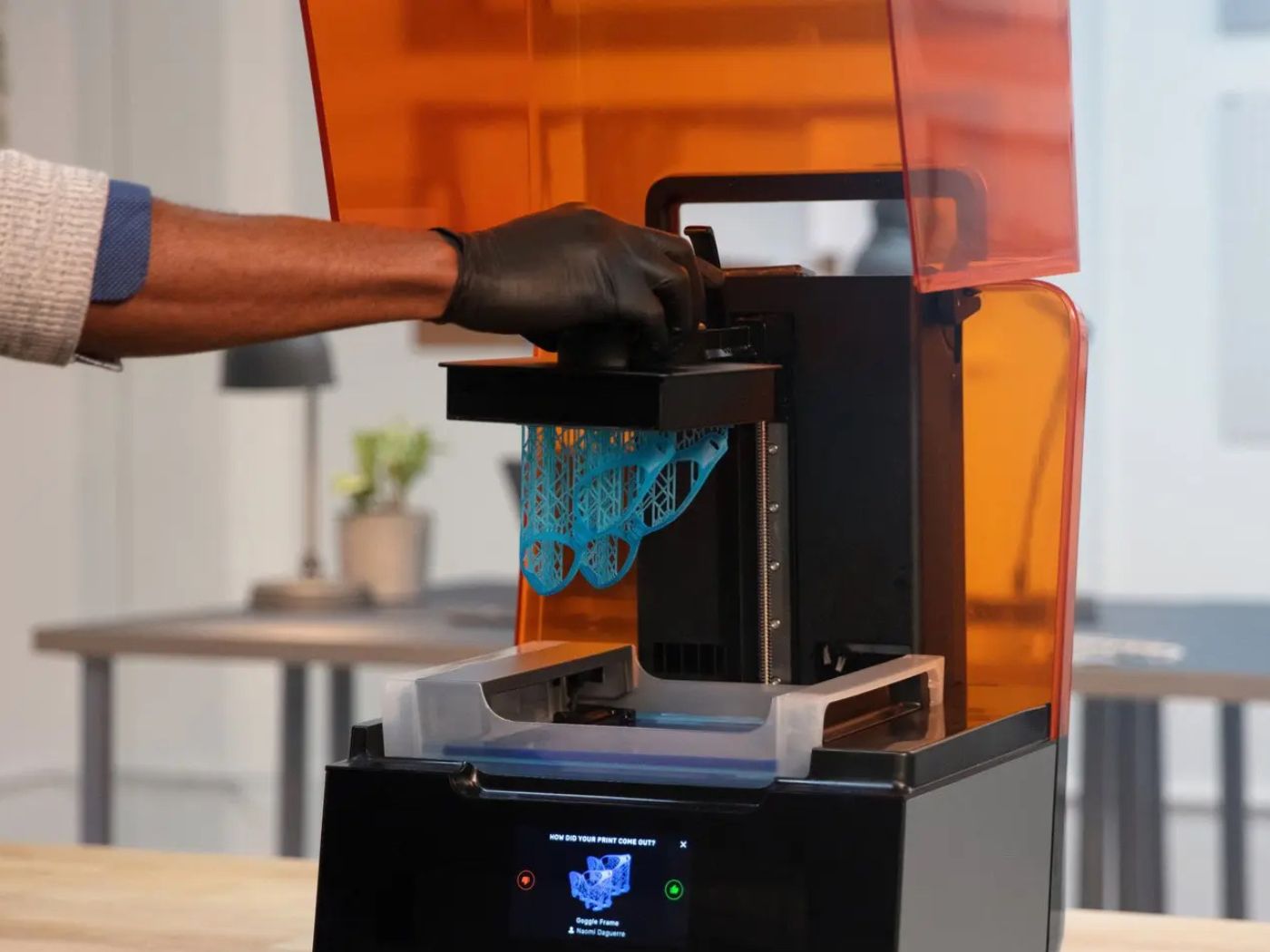

1. Filament Dryer

Our top recommendation is to use a filament dryer. It is a purpose-built dry box not only for drying your filament but also for storing your filament and keeping it free from dust and particulates.

The Sunlu FilaDryer S4 is the first filament dryer on the market that can dry and store up to four spools (4 kg) of filament at the same time and is fairly affordable. It has eight holes and PTFE cubes that allow concurrent printing on multiple FDM printers while drying filaments. Its fast heating (can heat up from 25 °C to 70 ˚C in 80 mins), temperature balance, auto humidity control, and universal compatibility make this S4 FilaDryer super easy to use. All you need to do is adjust the temperature and heating time on a large LED touchscreen.

2. Oven

The most commonly used household appliance and probably the easiest way to dry your filament is to use your oven. It's like baking a cake; you need to preheat the oven to a specific temperature. It is recommended to set the temperature slightly lower for a specific type of filament to prevent overheating. Therefore, you can use a glass thermometer to ensure the exact temperature of your oven and easily maintain it.

Following are the suitable target temperatures for some of the most common filaments:

|

Material Temperature Time in Oven |

|

PLA 40°C-50°C 4-6 hours ABS 65°C-75°C 4-6 hours Nylon 75°C-90°C 4-6 hours PC 80°C-90°C 7-10 hours |

Keep in mind that, as convenient as the oven is, you run the risk of melting all the plastic and fusing your entire spool together. Moreover, some filaments, like ABS, may contain an unpleasant smell. If you intend to use your oven to prepare food after your filament has finished drying, always allow time for ventilation.

3. Food Dehydrator

You can also place the filament spool inside a food dehydrator, remove the tray and use it to slowly remove excess moisture by providing low heat, which allows the filament placed in it to last longer.

To prevent your filament from turning into a molten heap, you should set the temperature slightly below the glass transition temperature of the material you are drying.

|

Material Temperature |

|

PLA 40-45 °C ABS ~80 °C (or highest available temperature) Nylon ~80 °C (or highest available temperature) |

Similar to drying with an oven, a dehydrator is originally designed for food. Since some filaments emit harmful fumes when heated, you need to keep these devices separate from what you would use for your food. Alternatively, ensure there is enough time for ventilation after finishing the drying process.

How To Store Dried Filament?

After drying your filament, it's essential to store it in a dry place with low humidity. You can store your spools individually in sealable bags, such as vacuum storage bags. Click here to learn techniques and tips for storing 3D printer filament.

We hope the above easy, effective, and budget-friendly filament drying methods can help you store your filaments properly so that they can last for a long time.

Keep in mind that proper storage is the key here. Even if you store your dry filament properly and keep it in a humidity-controlled room, it can only prevent it from absorbing more moisture. If your filament becomes wet again, you'll have to dry it using the methods described above.